-

Modelling for

Performance and Controls -

Software Engineering

for Controls -

Control Algorithms

Design for Innovative Products -

Control Systems Design

for Established Processes -

Safety

Analysis

Modelling for Performance and Controls

Control system design revolves around creating a clear transient model for the system being

controlled. This model should accurately represent all relevant dynamics while avoiding unnecessary complexity. Our expertise lies in defining, implementing, and parameterizing dynamic models across diverse domains, encompassing:

- Mechanical

- Electrical

- Thermodynamic

- Aeroelastic and fluidodynamic

Case studies

Goal statement:

In a thermal energy storage plant, control algorithms play a primary role in achieving:

- Best Round Trip Efficiency (RTE)

- Compliance with grid norms

- Plant operational capabilities

At the same time, such algorithms also keep plant operating parameters within the design limitations of plant components, such as turbomachinery, heat exchangers, tanks, piping, etc.

Solution provided:

A comprehensive dynamic model of the plant is built, integrating equations from different domains (thermodynamic, electrical, etc.). The optimum trade-off in model complexity is set taking into account PFDs and P&IDs. Such model is built to be interfaced in closed loop with the control software. Hence a framework for developing, maintaining and versioning the model, the control software and its tunings is put in place. Control software architecture and functionalities are then developed with fast iterations allowed by the model-in-the-loop simulations. The simulation iterations are made more powerful by a pre/post processing toolchain. The preprocessing allows agile parallel execution of a high number of simulations, which combined represent the whole spectrum of the plant operations and environmental variabilities, without relying on human input unless strictly needed. The post-processing toolchain operates on the executed simulations to produce automatically generated reports, optimizing the use of analysts’ time.

Control functionalities integrate the whole spectrum of traditional closed loop solutions, model based optimum controls, estimation of non measurable variables, along with the discrete domain solutions such as finite state machines and algebraic logics. Algorithms are tuned to comply with requirements from all the above-mentioned sources (RTE, grid norms, operability). Compliance to requirements is documented for all internal customers and external partners.

The control code is documented for EPC specifications where a DCS target is contemplated, while other code fractions are used to directly generate and deploy a PLC code. Field commissioning and performance

validation follow.

Problem statement:

Wind energy is renewable and environmentally friendly. Its main weakness is that when the wind speed drops, so does the power that a wind turbine can deliver to the grid. A wind turbine manufacturer wants therefore to explore possibilities to make the power delivery of their plants immune to the natural oscillations of the wind by means of energy storage electrical devices to buffer power between the turbine and the grid. The chosen energy storage devices are super- capacitors, and Li-Ion batteries to fit into the turbine tower.

Solution provided:

We design, implement and run the dynamic models of such energy storage devices. We integrate them with the turbine model to assess the power delivery at low voltage stage. The study seeks and achieves optimum size and combination of super-capacitors and batteries to leverage their respective strengths.

Upon this result, the business case is made.

Problem statement:

When estimating parameters of a mechanical system in resonance, it is typically the damping value that poses the biggest challenge, more so than the inertial and stiffness values. A wind turbine manufacturer questions its own design conditions when actual first-mode tower oscillations are suspected to be less structurally damped than was hypothesized during the development phase. The most significant source of tower oscillations damping in wind turbines are the aerodynamic properties of the rotor themselves, meaning that the tower structural damping is even less immediately observable in the tower top acceleration data.

Solution provided:

The tower top acceleration data is preselected according to the following validity conditions:

Blades are at feather position, right after a stop manoeuvre. This allows having the minimum aerodynamic damping factor in the fore-aft motion, while the elastic energy released in the stop manoeuvre is still relevant and exciting the fore-aft motion itself.

There is observable fore-aft tower top motion, while there is no relevant energy transfer to the side- side motion where aerodynamic damping would still intervene. Side-side motion has a neglectable amplitude. The fore-aft tower top acceleration can then be used, under the conditions above, to estimate the inertial, elastic and damping factors associated to the first mode of vibrations of the tower, according to a classic least-square-error methodology exploring the space of parameters. The identified damping value is 25% lower than the design hypothesis. Design simulations are re-run accordingly, resulting in a non-neglectable increase in tower bottom fatigue. The early integration of knowledge from field data back into the design allows for a timely deployment of further active damping control strategies, bringing plant operations back within the fatigue design envelope, thereby ensuring the certified longevity of the turbine’s structure.

Software Engineering

for Controls

The core value of control systems lies in their algorithms, logic, code, and parameters — essentially,

the software. This software serves as a cornerstone in industrial plant design, often having a life span

of several decades.

At Roumtech, we provide tailored software frameworks to meet the specific needs of control system software. These frameworks typically enable:

- Intuitive, requirement-driven high-level design and development

- Methodical and streamlined implementation

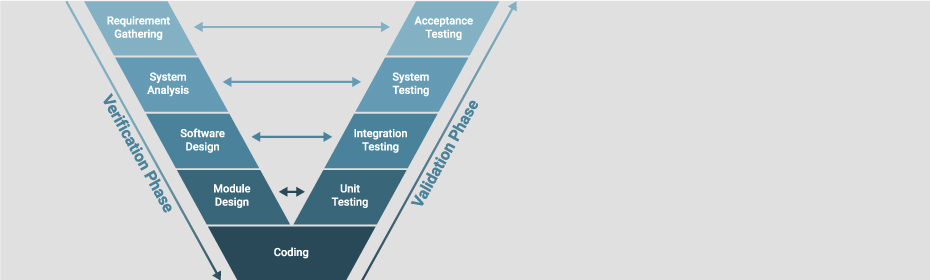

- Rapid and seamless debugging, unit testing, and integration testing

- Comprehensive verification against requirements, performance validation, and robustness assessment

Additionally, our frameworks benefit from:

- Pre- and post-processing toolchains designed to execute extensive simulations and synthesize results in a fully automated manner. This automation of design simulations frees engineers from repetitive, low-value execution tasks, allowing more time for high-value activities such as planning, analysis, and decision-making

- A cutting-edge, organic, and modularized versioning system

- Dedicated databases for parametric values, effectively managing the complexity of various product configurations and generations

Case studies

Problem statement:

A baseline control software system (system “A”) is designed to fulfil power curve and loads requirements (requirements “A”), which allow entering the market at a certain time.

Over time, loads-based requirements become more elaborate (requirements “B”). System “A” hence grows into system “B” to keep up with the market. The growth of the software system from “A” to “B” is performed focusing on speed, neglecting design coherency and long term maintainability. Requirements “B” are still met, creating the illusion that the system is on an effective track.

Then market raises the bar again, when grid norms and availability-related needs merge into a completely new set of requirements (requirements “C”). At that point System “B” shows its weakness: because of the accumulated dis-organic complexity, further changes to system “B” produce uncontrollable unwanted effects. System “B” cannot grow anymore and hence cannot keep up with the market.

Solution provided:

The desired functionalities of system “B”, to achieve the certified loads and power curve, are identified by means of reverse engineering, as documentation has not been kept up to pace with code. A new comprehensive software architecture is designed to incorporate past and future features in an organic fashion, and it is documented from the highest abstraction level. Meanwhile a thoroughly defined design philosophy is adopted to guarantee sustainability of future growth.

System “C” is hence born, according to the new architecture and philosophy. System “C” is proven to reproduce all expected behaviours of system “B”, without the unwanted ones, hence maintaining the effectiveness of the already certified loads and power curve. Changes to comply with grid norms and achieve the needed availability (requirements “C”) are also implemented on system “C”. From this point on, growth pace can be restored, and as long as the design philosophy and architecture are respected, there will be no blocking points in future development. The rigorous application of the software modularisation principle in the new design philosophy also improves team spirit and collaboration during parallel development, because conflicts in reintegration of branched code onto the trunk are virtually eliminated.

Problem statement:

The customer’s control staff is distributed among different projects, each employing its own software development framework. This decentralized approach leads to duplicated efforts, with each project team starting from scratch for every new project, meeting and solving the same challenges each time.

Valuable lessons learned are not systematically shared among teams. Furthermore, the existence of multiple library instances complicates matters, as teams struggle to identify and maintain optimal solutions.

Solution provided:

To address these challenges, we have introduced a comprehensive new development framework. It merges the expertise of Roumtech with the specific requirements, processes, and practices of each project team. Libraries are consolidated and centralized, enhancing knowledge sharing and eliminating redundancies. The resulting framework has been quickly adopted as the standard across all project teams, facilitating collaboration and reducing redundant work.

Control Algorithms

Design for Innovative Products

We specialize in the design, implementation, validation, and maintenance of control algorithms across the entire lifespan of a product. Our expertise extends to system-level specifications, developed collaboratively with our clients, as control algorithms frequently have a defining impact on the product as a whole.

We have extensive experience in all the relevant control algorithm families, including:

- SISO and MIMO closed loops

- State machines based on standard discrete and continuous automata models, tailored as needed for specific project requirements

- Model predictive, robust, optimum, and various other model-based control theories from literature

Addressing the estimation aspect of control challenges, we confidently apply several digital filtering techniques. Our expertise ranges from ARMA structures for fundamental SISO requirements to advanced model-based, optimal observers such as Kalman filters and their nonlinear extensions.

We leverage AI-based tools to:

- Bridge modelling gaps where increasing the complexity of white-box models is not economically feasible, but a black-box approach proves effective with sufficient data quantity and quality

- Offer a secondary qualifying opinion on specific parameters estimated by other algorithms, enhancing overall algorithmic robustness and reliability

Case studies

Goal statement:

In a thermal energy storage plant, control algorithms play a primary role in achieving:

- Best Round Trip Efficiency (RTE)

- Compliance with grid norms

- Plant operational capabilities

At the same time, such algorithms also keep plant operating parameters within the design limitations of plant components, such as turbomachinery, heat exchangers, tanks, piping, etc.

Solution provided:

A comprehensive dynamic model of the plant is built, integrating equations from different domains (thermodynamic, electrical, etc.). The optimum trade-off in model complexity is set taking into account PFDs and P&IDs. Such model is built to be interfaced in closed loop with the control software. Hence a framework for developing, maintaining and versioning the model, the control software and its tunings is put in place. Control software architecture and functionalities are then developed with fast iterations allowed by the model-in-the-loop simulations. The simulation iterations are made more powerful by a pre/post processing toolchain. The preprocessing allows agile parallel execution of a high number of simulations, which combined represent the whole spectrum of the plant operations and environmental variabilities, without relying on human input unless strictly needed. The post-processing toolchain operates on the executed simulations to produce automatically generated reports, optimizing the use of analysts’ time.

Control functionalities integrate the whole spectrum of traditional closed loop solutions, model based optimum controls, estimation of non measurable variables, along with the discrete domain solutions such as finite state machines and algebraic logics. Algorithms are tuned to comply with requirements from all the above-mentioned sources (RTE, grid norms, operability). Compliance to requirements is documented for all internal customers and external partners.

The control code is documented for EPC specifications where a DCS target is contemplated, while other code fractions are used to directly generate and deploy a PLC code. Field commissioning and performance

validation follow.

Problem statement:

The state of charge of a battery is a non-measurable internal state. Measurable variables of a battery include voltage, current, temperature. Mathematically, the state of charge is the integral of the past current, both charging and discharging. However computationally a simple integration is not feasible because of the intrinsic instability of the integration process (even a slightest bias would result in a diverging error).

The state of charge is also correlated with the battery voltage. The strength of such correlation depends on the specific chemical makeup of the battery, but generally the voltage is much more affected by present and short-term past current than by long-term state of charge variations.

Solution provided:

Through lab-controlled tests, where the state of charge can be considered known, the battery hysteresis dynamics, i.e. the battery voltage response, is modelled as a dynamic function of current, temperature and state of charge. For the real time estimation on vehicles two models are then used. An inverted model returning state of charge as a function of current, voltage and temperature is used for short-term open-loop estimation.

A direct model returning voltage as a function of current, temperature and state of charge is used to compare the estimated voltage with the measured voltage. The voltage estimation error thus obtained is used for long-term, closed-loop, slow correction of the state of charge estimation. Combining the direct with the inverse model leads to a valid real-time state of charge estimation, allowing for optimum use of the hybrid power train. The estimation algorithm is validated in lab conditions and on vehicle.

Control Systems Design

for Established Processes

We offer control hardware and software development services tailored for established processes.

Typically, our clients provide:

- Piping and instrumentation diagrams

- Process and control narratives

- Alarms, interlocks, and shutdown definitions

With these inputs, we define hardware architecture and I/O lists, design and implement control software and HMIs. After initial validation in the laboratory, we support clients through factory and site acceptance tests until every aspect of the control system meets specifications.

Safety

Analysis

Safety systems often operate similarly to control systems, yet their design approaches differ significantly. We offer a comprehensive range of services to realize safety functionalities, from initial concept to full certification. Our work adheres to normative frameworks such as IEC 61508 and ISO 13849, as well as to industry-specific standards like IEC 61511, ISO 26262, IEC 61400, IECRE OD501-4. Our analysis encompasses FMEAs, Hazops, SIL/PL assessments, and calculations. Accordingly, we can:

- Define interlocks, process and safety shutdowns

- Determine necessary redundancies and component reliability

- Implement design actions aimed at risk mitigation